Production

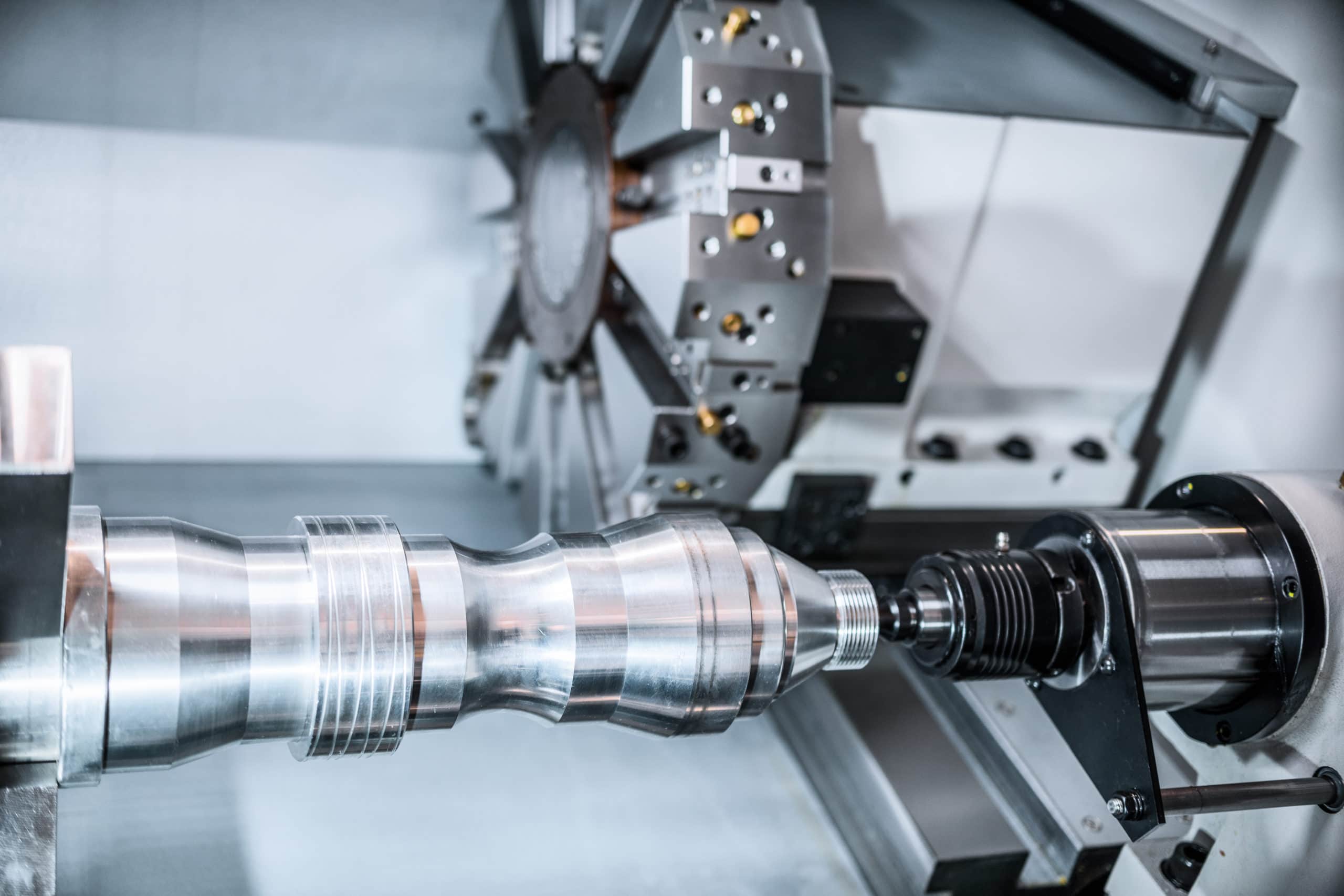

Precision manufacturing at the highest level

Production

Our company offers comprehensive services in the field of machining and production of metal and plastic parts. We carry out both single orders, small series and batch production, adapting to the specific requirements of our customers. We have a modern machinery park and highly qualified technical staff, which allows us to provide products of the highest precision and durability.

Key strengths of our production

Customized fit

We implement projects according to customer requirements, ensuring precise execution and optimal performance.

Modern technologies

We use advanced CNC machines, process automation and high-quality materials, which translates into product durability and precision.

Quality control

Each stage of production is subject to strict control, which guarantees repeatability and compliance with the required standards.

Experience and know-how

We have many years of experience in the industry, which allows us to offer innovative and effective solutions.

PRODUCTION ZAMEL

Machine parts

We manufacture mechanical components for industrial machinery and equipment, including:- drive parts, e.g.: shafts, wheels, bushings

- operating elements, e.g.: pan, pins, guides

- structural components, e.g. bodies, housings, welded structures

Injection, blow molds and casting molds

We design and manufacture molds for metal and plastic products. Our molds are characterized by:- High-precision reproduction of details,

- Optimized design to increase production efficiency,

- long service life and resistance to intensive use.

Tools for forming

We manufacture specialized metal forming tools such as:- stampers,

- trimmings,

- stamps,

- matrices.

Assembly and control and measuring instruments

We manufacture precision instruments to support assembly and inspection processes, including:- welding instruments,

- mounting brackets,

- control templates,

- measuring instruments for verifying the geometry and dimensions of components.

Special tools

We offer custom tools tailored to specific manufacturing processes, such as:- Milling heads for precision surface machining,

- Chamfering heads for precise edge preparation of structural components.

By choosing us, you are choosing competence, capability and quality.

Experienced specialists, modern machinery and strict quality procedures are the foundation of our business. As a result, we offer a wide range of services at the highest level, meeting the expectations of even the most demanding customers.

We serve companies in the country, the EU and the US, which confirms our competence and attention to detail.

Phone

E-mail address

Orderfree quote

Are you planning a project and need a quote?

Contact our sales department, who will advise you on the best solution and prepare a personalized quote for you.